The urban sphere is undergoing a significant transformation. Automotive mobility is transitioning towards more autonomous and cleaner practices. Public transport is simultaneously improving, expanding, and in some instances, fares are even becoming free. Ecological awareness is driving a change where roads are turning into vehicle-free zones, and entire city districts are kept clear of cars with high pollutant emissions. At the same time, entirely new mobility modes are emerging, giving rise to novel means of transportation, along with new challenges regarding their design and production.

The Cologne-based CNC carpentry, Bächer Bergmann GmbH, specializes in the manufacturing of transport boxes for various logistics and transport companies using diverse types of bicycle-based vehicles. With the growing demand for sustainable, clean, reliable, and fast urban delivery systems, the need for unique solutions is also escalating. Food supply, the transportation of children, trash removal, battery swapping for e-scooters, taxis, and the delivery of post, packages, and cargo – all have specific requirements.

However, the bulk of existing products are mass-manufactured and often unable to meet specific requirements regarding size, safety, and adaptability. While the transportation of the requested items is largely carbon-neutral, the materials used in the making of these systems are often not. This situation creates a contradiction with the ecological claims these companies make.

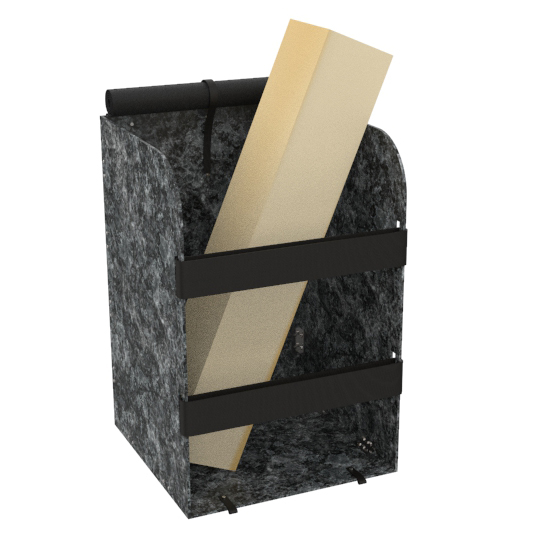

In partnership with Bächer Bergmann GmbH, the aim of this course was to develop innovative designs for transportation containers, establish customizable processes for robotic or similar digital manufacturing methods, and identify materials that meet the necessary requirements. The containers should be extremely lightweight, durable, water and weather-resistant, and shock-resistant. They should also be easy to repair, biodegradable, sustainable, or recyclable, and, if possible, fit the size of a euro-pallet (80 x 120 cm). This project presents a substantial step towards innovative, sustainable, and adaptable urban transportation solutions.