For the US author and mycologist Paul Stamets, the answer is simple: “Mushrooms will save the World”. In his book Mycelium Running, he not only vividly describes the many health-promoting properties of fungi, but also explains how they purify air and soil, filter and break down pollutants, provide nutrients for insects and microorganisms, and sustainably promote the growth and development of plants and the environment. The project, split into four phases, aimed to create a balance between the need for innovative, sustainable products and the environmental impact of unnecessary material objects. It revolved around three intertwined topics:

- Production of biodegradable starch-based material.

- Design of containers intended for fungal growth.

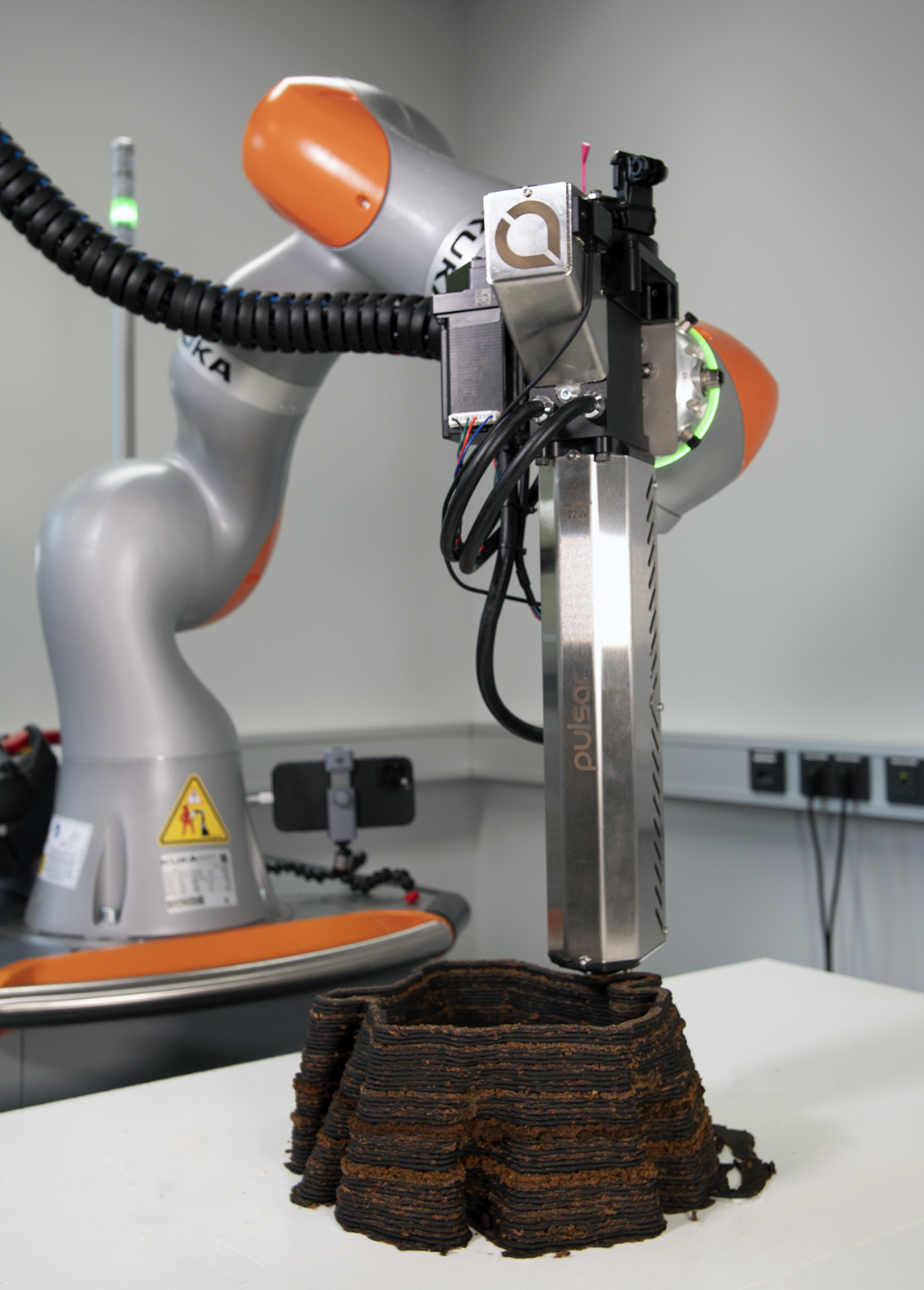

- Robotic 3D printing of the envisioned forms using the self-made material.

The central theme was not strictly about the fungi, but more about the design and manufacture of appropriate materials and their further processing. Emphasis was placed on the belief, as posited by American designer Neri Oxman, that material always comes first in nature. The properties of the material determine the structure of the organism, which in turn, shapes its form and appearance.

In Phase 1, the focus was on material production. Students used a printer that processed pellets, leading to the creation of specific printable materials. A range of bioplastic mixtures were created, based on starch and various additives, subsequently processed into strands, dried, and converted into pellets.

Phase 2 encompassed the design process, combining a variety of requirements. These included visual aesthetics and the context-dependent form and structure of the “mushroom vessels”, as well as their technical feasibility. With robotic 3D printing technology, understanding its potential and limitations was crucial for the successful implementation of the design.