Moving beyond Sustainability into Regeneration

How can bio-based polyester support a truly circular fashion economy?

Introduction

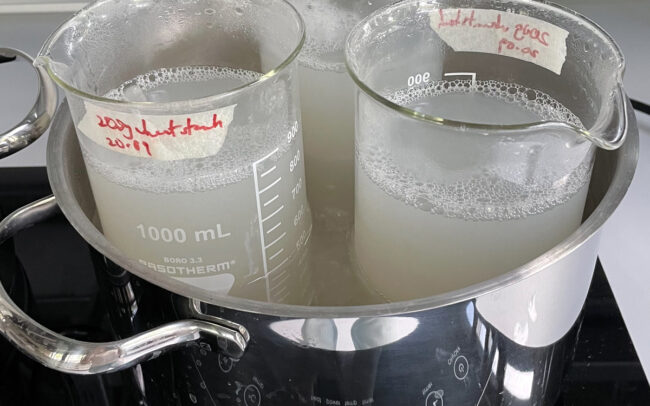

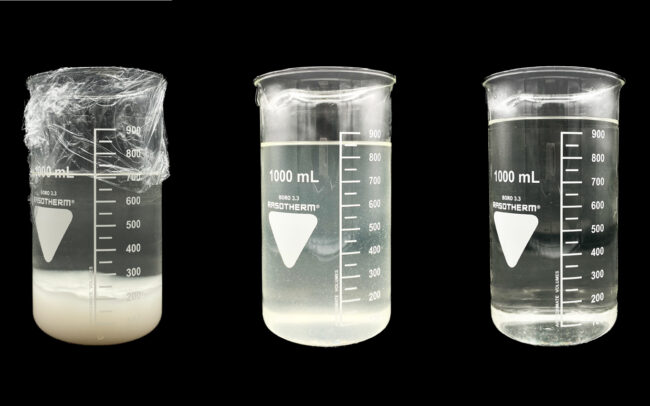

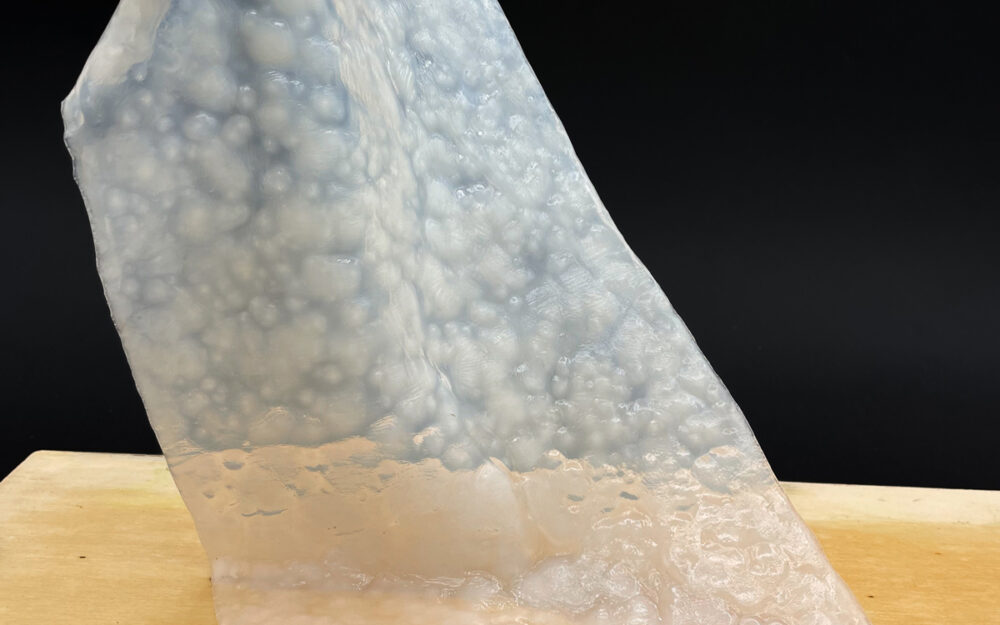

Biopolyester is a master’s thesis focused on the imperative need for transforming the fashion industry’s supply chain towards a circular production and consumption.

Polyester stands out as the most widely produced and utilized fabric in the fashion sector, despite its substantial environmental impact across its lifecycle, encompassing carbon emissions, pollution, microplastic release, and landfill accumulation. Yet synthetic fibers are forecasted to comprise 98% of all future fibers, 95% of which is expected to be polyester.

Through the fusion of design, material science, and circularity, the research aim is to develop a regenerative material to replace petroleum-based polyester. By focusing on the material composition of what makes our clothes, we are targeting the problem at its core, addressing concerns of microplastic release, carbon emissions, pollution, and landfill accumulation.