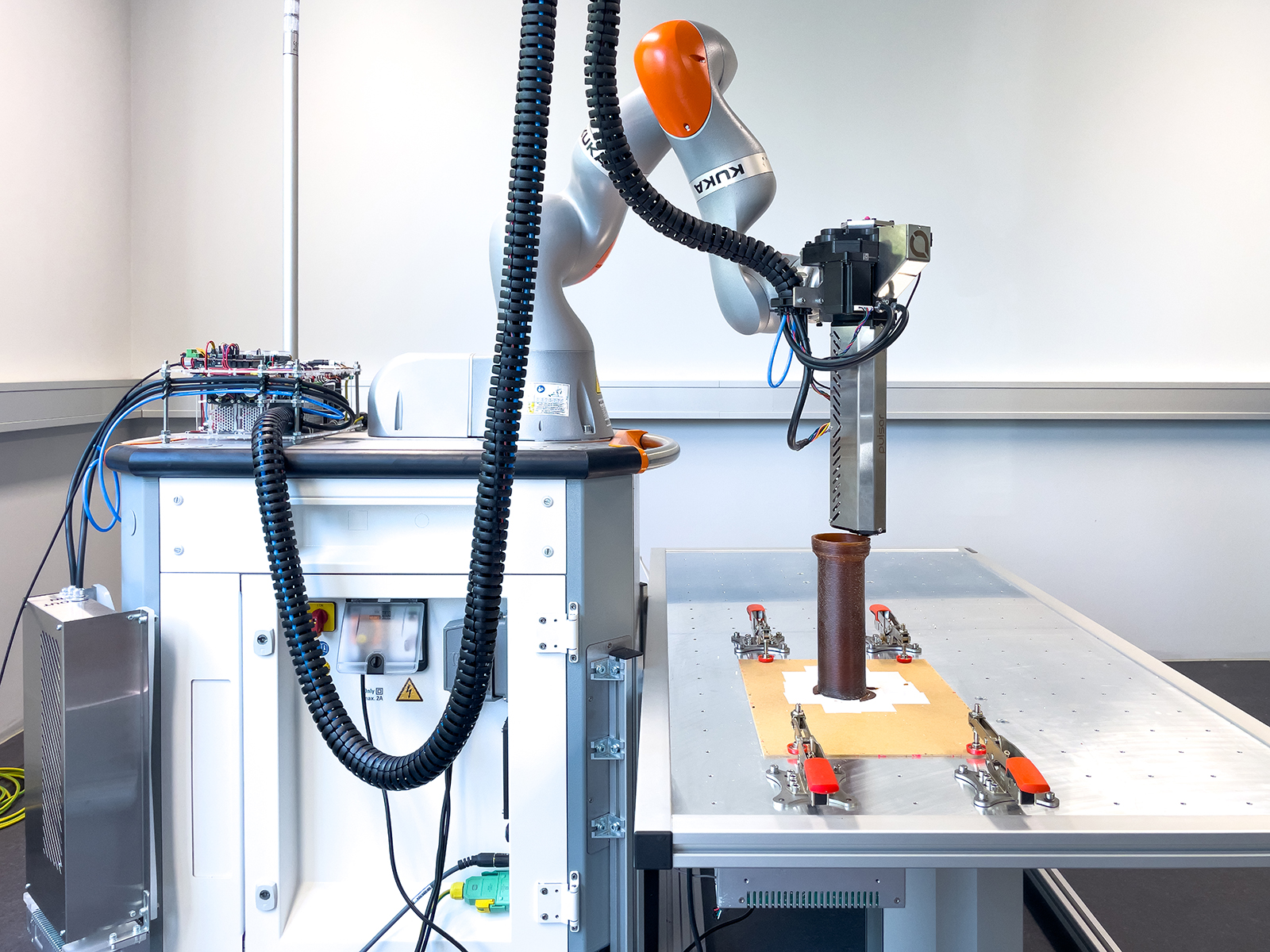

Large-scale robotic 3D printing of bio-based and biodegradable materials for non-standardized, single-use formwork in architecture

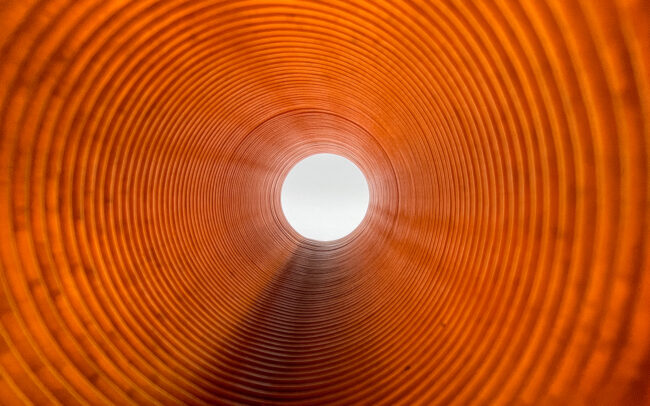

The following research investigates bio-based and biodegradable polymers for concrete formworks. It proposes synthesizing biopolymers with digital fabrication tools, such as robotic 3D printing, to complement existing research on reducing the amount of concrete used in buildings.

The climate crisis challenges architects, designers, and engineers to explore alternative opportunities for more sustainable fabrication processes. Biopolymers have emerged as a potential material to replace petroleum-based plastics used in building and construction processes. Simultaneously, existing research outlines how formworks can be 3D printed with plastics to reduce the required amount of material used in the formwork assembly. Printed formworks allow for individualized concrete elements that create material-optimized concrete structures. Additionally, printed formworks help minimize the use of non-renewable resources while decreasing the amount of on- and off-site labor in the construction process.