using microbes to grow biological fabrics

This biological alternative to leather is made from cellulose nanofibrils spun by bacteria and yeast. The material can be treated similar to traditional textiles and dried into sheet form, or molded around a form during the drying process. Microbial leather has the potential to become an alternative to animal leather and their harmful environmental impacts.

Materials and Tools

|

|

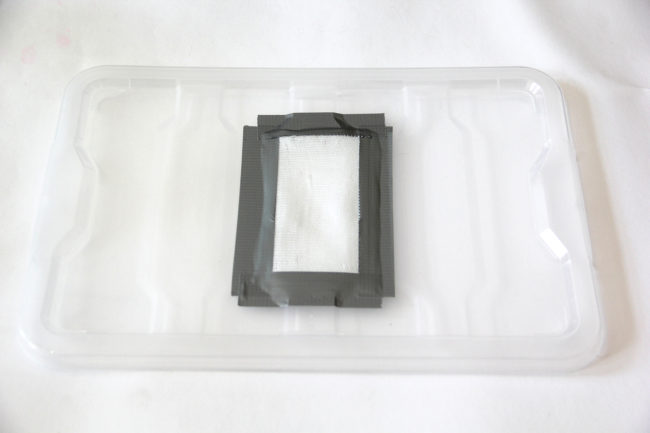

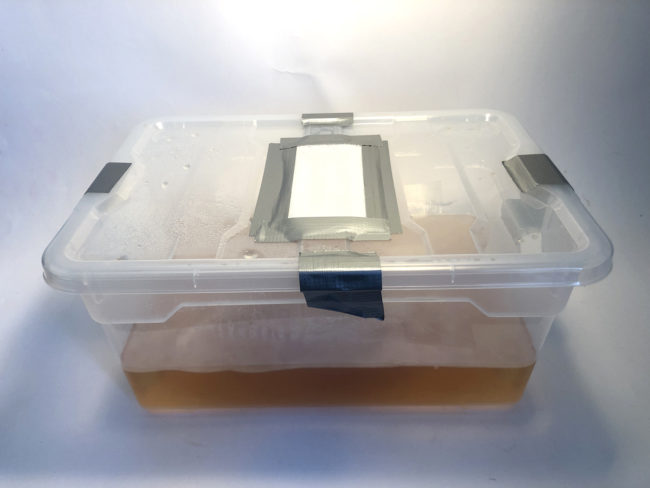

1. Preparing Container

Cut a roughly 6 x 6 cm large hole into the container lid. Adhere the breathable cloth patch with duct tape. (This is to let oxygen in, keep heat in, and keep insects out.) Then thoroughly clean the container with rubbing alcohol. Make sure to sterilise the lid, too.

2. Making Tea

Pour 2 l of water into a clean pot and bring to a boil. Remove the pot from heat and add 3 tea bags. Leave the bags inside the hot water for 15 minutes, then remove them. Add 240 g of granulated sugar and stir the mixture until it has completely dissolved.

3. Preparing Growth Medium

Pour the hot liquid into the sterilised container and add one more liter of cold water. Then add 200 ml organic cider vinegar and stir the mixture. Let the liquid cool to room temperature (below 30° C).

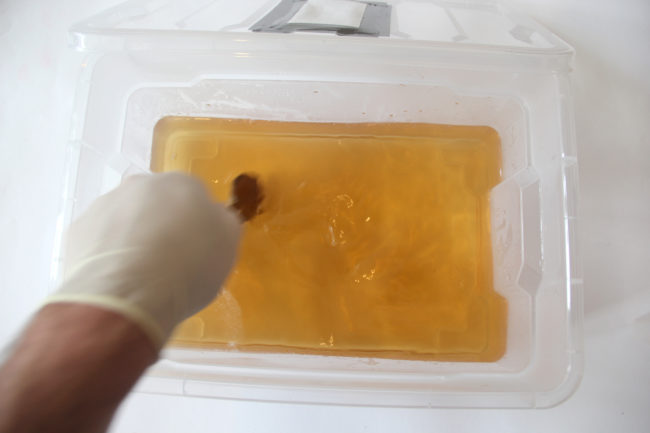

4. Adding live Culture

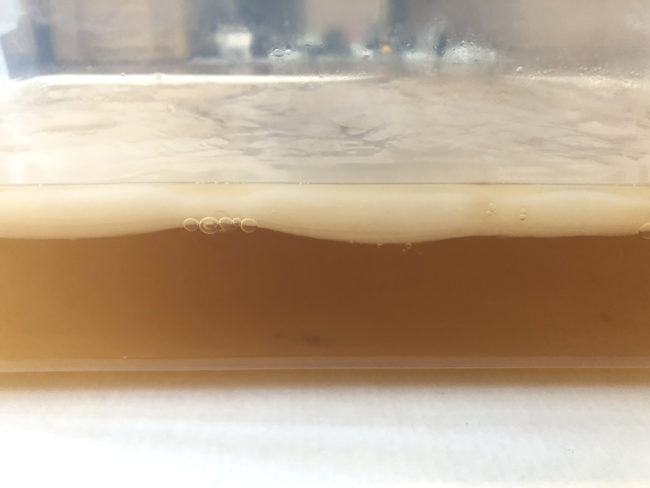

Make sure the liquid has cooled down. High temperature will damage the Kombucha culture. Add live Kombucha culture. It might sink to the bottom of the container. Close the lid and store the container in a warm (above 19° C) and dark area. Sunlight can harm the culture. Fermentation begins after 48–72 hours, thin skin and bubbles will appear and the culture will rise to the surface.

5. Growth

Check the container weekly with sterilized gloves to make sure there is no contamination. Within about 4 weeks the product will grow to about 1.5 – 2 cm in thickness. Then remove the sheet from the container.

6. Drying Leather

Wash the sheet with soapy water. Dish soap works well. Lay the soft sheet out to dry on a porous surface like wood, wire mesh, felt, etc. Drying can take about 1-2 weeks.