turning waste into a new material

Polystyrol (PS) is a well-known thermoplastic with the recycling number 06, a plastic that can be found in almost every supermarket shelf. It is the fourth most important plastic after Polyethylene (PET), Polypropylene (PP) and Polyvinylchlorid (PVC). In addition to its function as a packaging material for food, PS is used in switches and housings of electrical devices. Its expanded state EPS (also known as Styrofoam) is a popular material in model making and, due to its good insulating properties, it is one of the most used materials on construction sites. PS can be liquefied using Ethylacetat, a solvent made from Acetic Acid and Ethanol. In this process the solvent breaks the molecular chains of the PS. When the solvent evaporates, the plastic re-hardens and can be turned into a new shape.

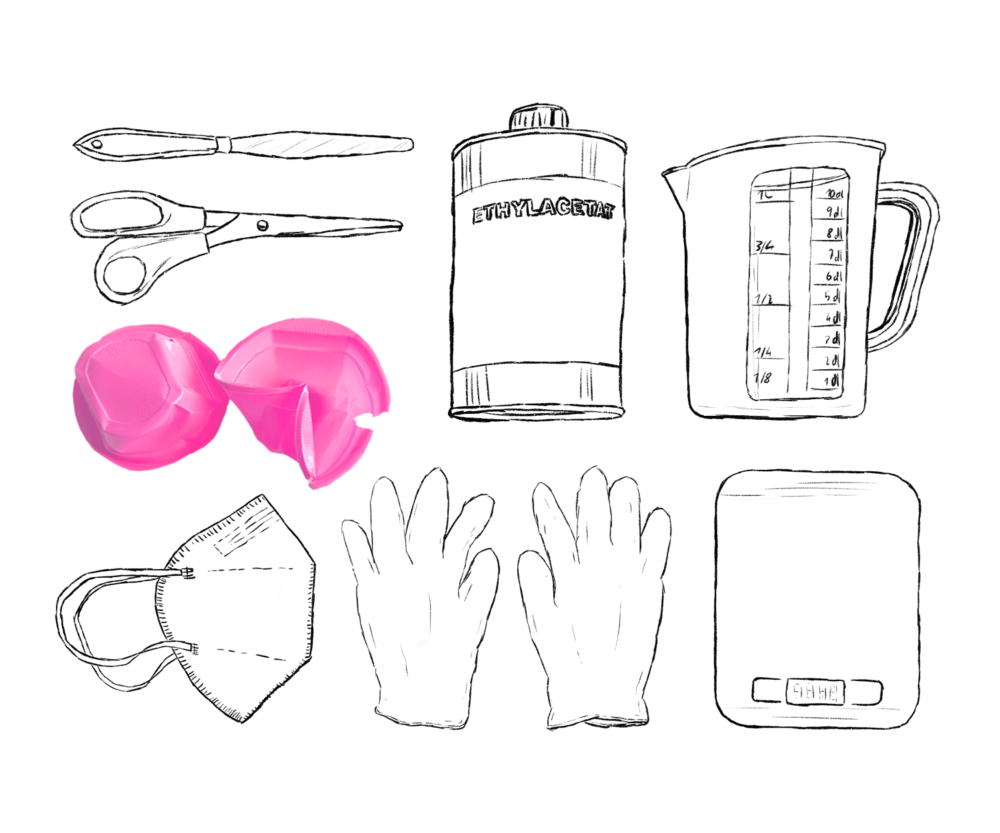

Materials and Tools

|

|

1. Preparation

During the first step, the previously sorted PS is thoroughly washed, cleaned, freed from stickers and other leftovers and then fully dried.

2. Shredding

Now use sharp scissors and cut the clean and dry plastic parts into small pieces of about 1 x 1 cm in size. Use a kitchen scale to weight the plastic in order to determine the correct amount of required solvent. Use your mask and gloves, fill the shredded plastic into a measuring jug and add Ethylacetat in a ratio of about 1:1 (10 g to 10 g).

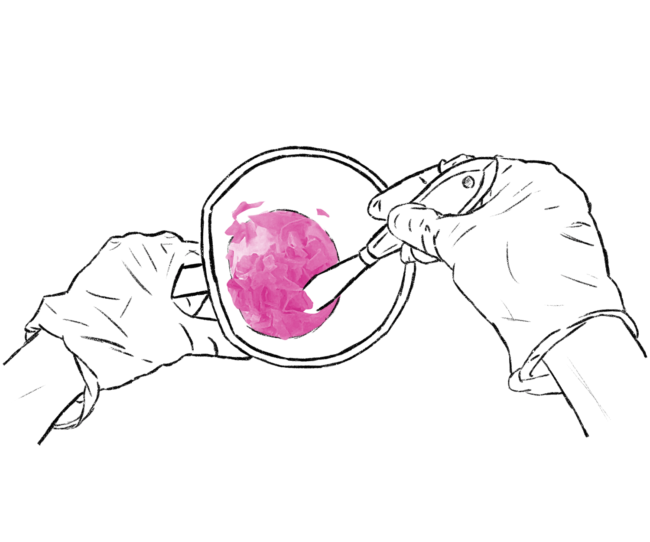

3. Liquefaction

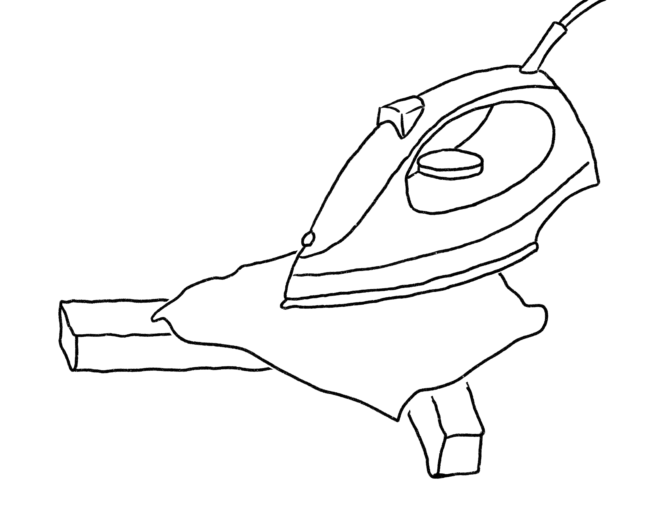

Stir the mixture using a wooden spatula until your desired consistency is reached. The approximate duration for 10 g is roughly 5-10 minutes. For a more liquid material simply add more solvent. The liquid plastic mass can now either be applied directly or stored in an airtight container for later usage. Since all Ethylacetate has to evaporate for the material to harden the drying process can take several days. This can be sped up with different techniques like for example using a flatiron that can help to both harden and shape the freshly applied material.

Video with instructions in German.