the use of bioplastics as a potential construction material

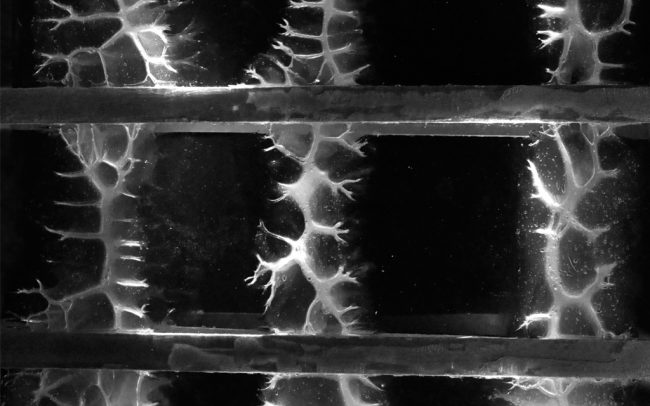

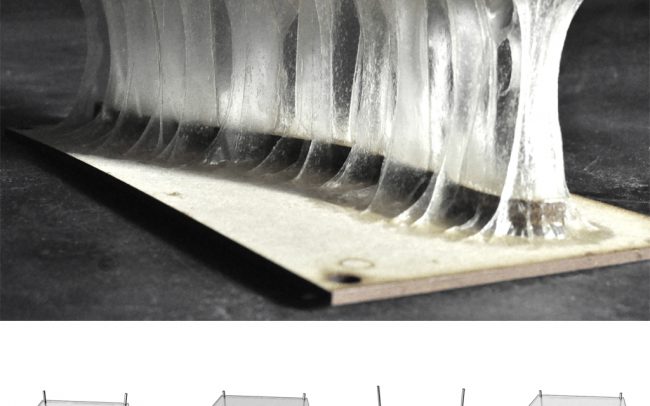

Making my own bioplastics was the first step taken. This process helped me understand how viscous materials behave. Bioplastics, being viscous materials, they can take whatever shape you force them to have. However, there is an interesting aspect of this type of material that can be explored. By elongating a viscous paste between two surfaces, the three dimensional volume that the material occupies increases one of its dimensions and subsequently the other two dimensions reduce. The bioplastic material is made out of long chains of polymers, therefore the result of the strain deformation is the creation of dendrites that converge towards the centre of the elongation distance. This configuration makes structural sense as it creates a multidirectional support system.

Changing the initial conditions of the surfaces and playing with difference types of elongation process, interesting forms can be achieved. This structurally sound system can then be applied as a brick system or a wall system. The base material used for the experiments shown in the pictures is potato and tapioca starch, mixed with water, vinegar and glycerine.

A more resistant polymeric material can be achieved by adding additives and various tests are required in order to obtain a material system that would resists major stresses.