a smart facade system using parametric allocation of photochromic agents to achieve passive shading

Chromatic Skins is a research project developed at the Institute for Advanced Architecture of Catalunya in 2014, bringing forth a potential architectural application of Color Changing Materials, namely Photochromic Pigments, as passive shading agents within parametrically configured façade systems.

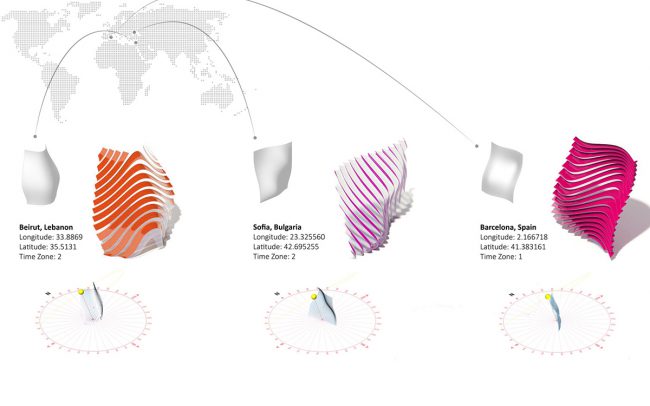

Inspired by Cuttlefish and its incredible ability to change color and pattern at unbeatable rate under different conditions, we explore how color changing substances as intelligent materials can adorn building skins to help respond to a spectrum of stimuli and communicate information about these changing states of heat and light at different times and locations around the world.

Photochromic pigments darken in proportion to exposure to UV light, a property greatly compatible with shading requirements in building design. However, this engineered material remains subject to great challenges, one of which is the economic factor that renders its application ridiculously expensive. Tinting our high-rise buildings holistically in photochromics simply sounds unreasonable. On the other hand, environmental analysis and simulation tools today are advanced enough to give insight on the solar exposure subjected to a surface of any form anywhere in the world.

Hence, we decided that the material must be efficiently distributed on a given surface. We developed a site and geometry-specific parametric tool offering a design solution for glazed facades with scalability options, to optimize system performance by efficiently allocating the photochromic agents.

Chromatic Skins optimizes at once the transparency/visibility of a given surface and its corresponding required shading.

The resulting performative skin is then verified using Ecotect, Radiance and Daysim for quantitative analysis. Ready for fabrication, the skin is tessellated and further details are developed for construction following a standardized process.

The first prototype serves as proof of concept. Hence a simplified version of the actual fabrication process was used: A 1mm acrylic sheet was vacuum formed and photochromic layers mixed with epoxy resin were applied over in stencils as per resulting digital patterns. We set up our own fabrication logistics and built a vacuum forming-machine using available wood materials and the vacuum hose of the CNC-milling machine available at IaaC Fab Lab.

The Styrofoam mold was 3D modeled and milled. The “Machine” consisted of the suction box having a grid of tiny holes and a bigger one where the vacuum hose goes; and the frame that holds the plastic sheet throughout with long handles to keep our hands from burning.

The fire is started and the acrylic sheet is firmly fixed to the upper part of the box. Using the long handles, the sheet is inserted into the fireplace, slightly moved around to heat the surface uniformly. The acrylic starts to melt slowly, developing a “belly”. It is at this point that it is taken out to be immediately applied over the mold, fixed in place, and closing off completely with the base box ensuring air tightness. This is crucial for the suction to be effective enough in forming the surface. This process is aided by a manual heat gun, used to melt the surface further to perfection. The process is far from being error free. The “belly” creates wrinkles as it meets the wavy surface of the mold; hence the need to consider the following:

1. Use thicker plastic sheets

2. Reduce heating time

3. Reduce overall size of mold

4. Reduce depth of valleys and crests in mold

5. Ensure air tightness

6. Use heat gun straight afterwards

Prototype 1 was put under the sun and the wavy form was put to test by flipping it over and comparing the resulting shadows. The proposed system works and the degree of required shade can be further controlled by defining the surface area to be covered with CC pigments. A dotted pattern may be employed and density controlled accordingly.