Expertise II | Material and Technology | University of Applied Sciences Anhalt

The workshop was building upon the 2018/19 collaborative course between the Dessau Department of Design and the Dessau Institute of Architecture Bioplastic Robotic Materialization supervised by Manuel Kretzer and Sina Mostafavi. The objective was to continue the exploration of the possibilities of custom-made bioplastic materials in combination with 3D printing to create generatively designed volumes, specifically aiming for a design for the Dessau Design Show Award 2021.

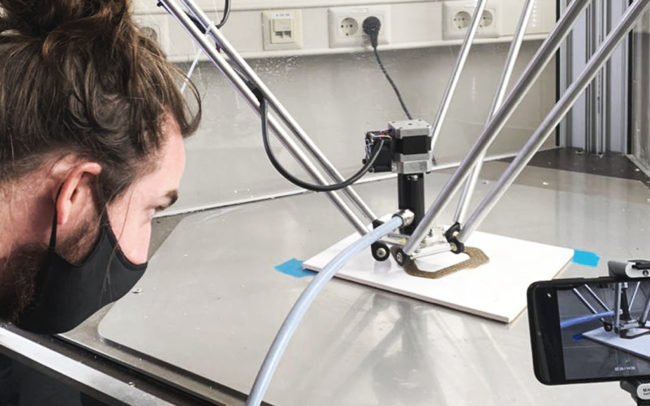

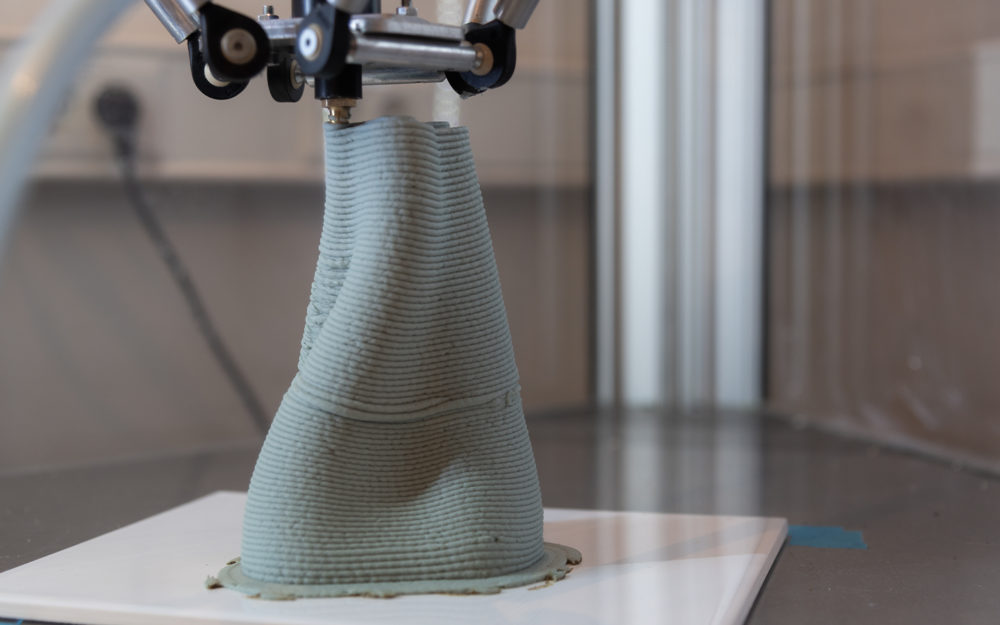

Students were asked to parametrically design the award employing their own custom-made Rhino/ Grasshopper scripts. Pushing the limits of LDM (Liquid Deposition Modeling) of biobased plastic printing, the objects should be about 200 mm high and 100 mm in diameter. The dimensions were aiming for results for clarification of the formstability of different mixtures.

The participants developed their specific bioplastic material for 3D printing with the WASP Delta 60100 printer, following a variety of different pretested base recipes and techniques. The composition should provide the right viscosity for LDM printing and dry fast enough so multiple layers can be added on top of each other without risking collapse, remain durable and tough after curing, and offer interesting visual and tactile features regarding the design task.

The recipes of bioplastics are simple and in general consist of three to five renewable biomass sources. A mixture is made of biopolymers, bio-plasticizers, and bio-additives. Biopolymers considered can be starch, gelatine, or agar agar. As bio-plasticizers usually glycerol or sorbitol are used. Further additives can be biowaste, such as coffee grounds or fruit skins, clay, vinegar, spirulina, sugar, soap, burlap, or hemp. Most bioplastics are water based and need to cure to reach a solidification state. Considering the above mentioned ingredients, a wide range of possible combinations and mixing ratios are conceivable. The goal is to incrementally and iteratively analyze mixtures and their ratios for plausible three dimensional deposition performances. Factors for evaluation are general material properties, such as strength, shrinkage, durability, cracking, color loss, curing time, pot life, additive energy sources (heating, cooling, and UV), viscosity, stickiness, workability, and processability. Further, costs for ingredients and preparation and the segregation between animal- and plant-based biomaterials will be considered.